Machining

Machining are the fundamental manufacturing method used in many areas such as aviation, space, defense, medical and automotive etc. In other words, machining serves as a backbone in many manufacturing industries. It can be applied using machine tools having various features, and accurate parts can be manufactured. Within this scope, our laboratory provides services to universities, public and private institutions with the following machine tools.

5 surfaces of the workpiece can be precisely milled in a single setup with this machine tool containing 5 axes. Furthermore, it is possible to manufacture complex parts by means of its 5-axis simultaneous capability. Due to its remarkable advantages, this machine tool is frequently used in many areas such as aviation, space, medical and automotive etc.

|

Machine specifications: X axis movement: 500 mm Y axis movement: 450 mm Z axis movement: 400 mm Maximum spindle speed: 10000 rpm Control unit: 3D-control Heidenhain iTNC 530 Position sensitivity: 20 µm Magazine capacity: 16 tools |

Many milling and drilling operations can be performed with this vertical machining center which has 4 (3+1) axes. With rotary axis (i.e., 4th axis), operations such as milling, drilling and grooving can be carried out on cylindrical/prismatic workpieces.

|

Machine specifications: X axis movement: 1020 mm Y axis movement: 510 mm Z axis movement: 400 mm Maximum spindle speed: 6000 rpm Control unit: Mitsubishi Magazine capacity: 20 tools |

Basically, in the turning process, the stationary cutting tool is moved axially and radially and chip is removed from the workpiece while the workpiece is rotated at a certain angular speed mounted on the machine spindle. By using CNC lathe, this process is precisely completed and accurate parts can be manufactured. Additionally, drilling and various milling operations on the cylindrical and prismatic workpieces can be performed with the C axis of the machine.

|

Machine specifications: Maximum turning diameter: 260 mm Maximum turning length: 550 mm Spindle speed range: 35-3500 rpm X-axis rapid travel speed: 12000 mm/min Z-axis rapid travel speed: 15000 mm/min Spindle power: 15 kW Control unit: Fanuc Turret capacity: 12 tools |

Electrical discharge machining (EDM), which is one of the non-traditional manufacturing methods, is widely used in many manufacturing industries. It machines the workpiece by means of electrical spark and is able to manufacture accurate parts having high surface quality. One of the main implementations of the EDM is the wire cutting. The wire used here serves as an electrode and the workpiece is cut with the spark occurring between the wire and the workpiece. With this process, it is possible to easily cut very hard materials. In addition, it allows to obtain very sharp corners, which is among the advantages of the wire cutting process. Due to the aforementioned advantages, wire cutting machines are frequently used especially in the molding industry.

|

Machine specifications: X axis movement: 910 mm Y axis movement: 710 mm Z axis movement: 395 mm Maximum working dimensions: 780 mm x 520 mm x 300 mm Wire diameter range: 0.2-0.33 mm Maximum workpiece weight: 500 kg Maximum material removal rate: 180 mm2/min Maximum working current: 25 A |

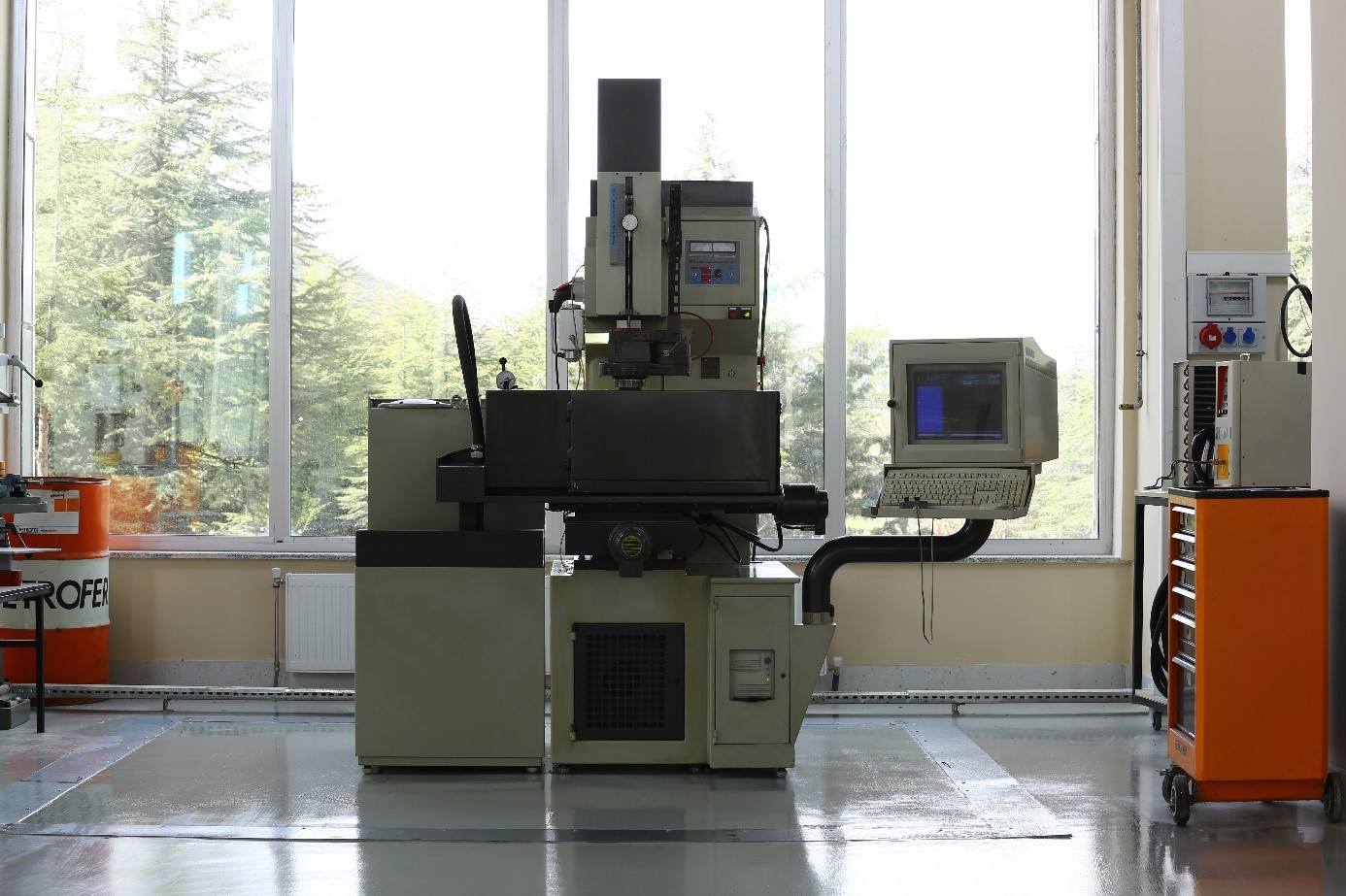

Die sinking is another implementation of EDM. In this process, the electrode of the desired shape to be formed on the workpiece is manufactured by other methods e.g., milling, turning, etc. It is then mounted on the machine head and the workpiece is axially machined.

|

Machine specifications: X axis movement: 370 mm Y axis movement: 270 mm Z axis movement: 230 mm Maximum workpiece weight: 300 kg Working tank dimensions: 750 mm x 470 mm x 300 mm Maximum axial movement speed: 600 mm/min Maximum material removal rate: 600 mm3/min |