Metallography

Olympus BX51TRF-6

|

Vertical layer travel: 25 (mm) Minimum setting degree: 1 (µm) Lens: 5x – 10x – 20x – 50x – 100x |

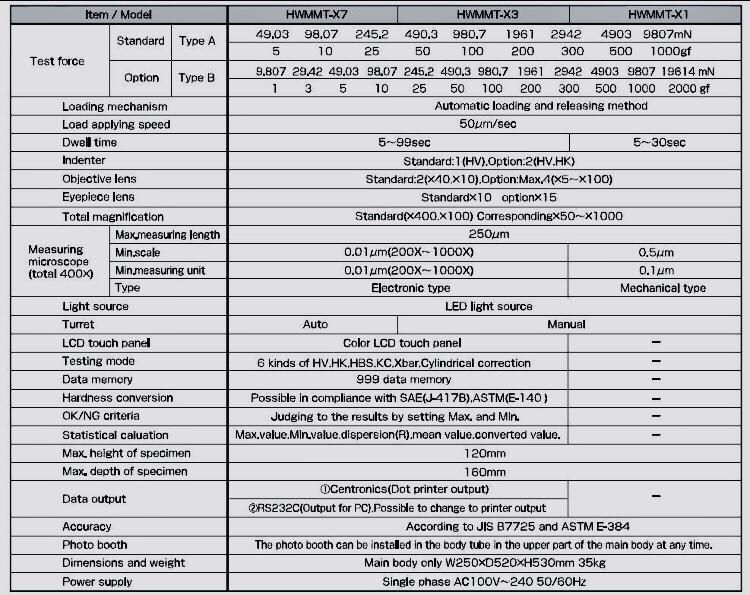

TTS Matsuzawa HWMMT-X3

|

Hardness measurement at micron level Microhardness measurement of materials that have undergone layer, coating and hardening processes can be made. |

UTS Tribometer T10

|

1- Pin-on disc 2- Ball-on disc 3- Oily environment 4- Dry environment 5- Linear Motion Mechanism (Reciprocating) Test samples should arrive ready in accordance with the test standard to be performed. Pin holder: 3-10 mm |

ATM GMBH Brilliant220

|

Before the operation is performed, the material information and geometry should be shared with the personnel and approval should be obtained. Maximum cutting capacity: Ø75 Cutting wheel: 75-203mm/8" Shaft size: Ø12.7mm Horizontal / Vertical Movement (X / Y axes) Table: 300x210mm Speed: 0.005 – 3 mm/second Sensitivity: 0.1mm Vertical travel (Y-axis): 80mm Horizontal travel (X-axis): 210mm Revolution Speed: 500 – 5000 rpm |

ATM GMBH Opal 410

|

Mold size: Ø40 mm Temperature range: 0-200 °C Heating time: 1-30 min Hydraulic pressure: 0-450 bar Cooling time: 1-30 min |

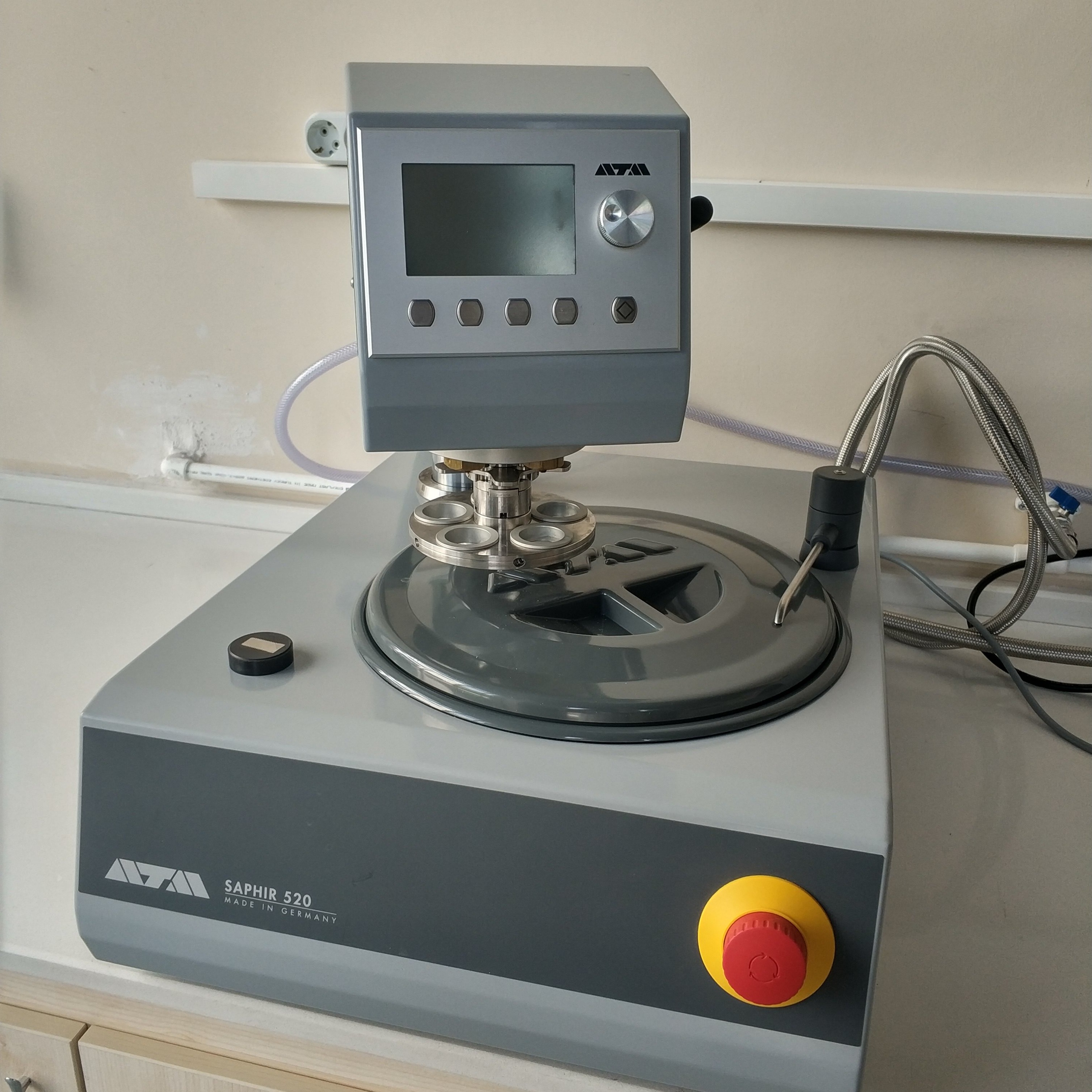

ATM GMBH Saphir 520

|

Connected load: 0.9 kW Full automation upper and lower rotating disc |

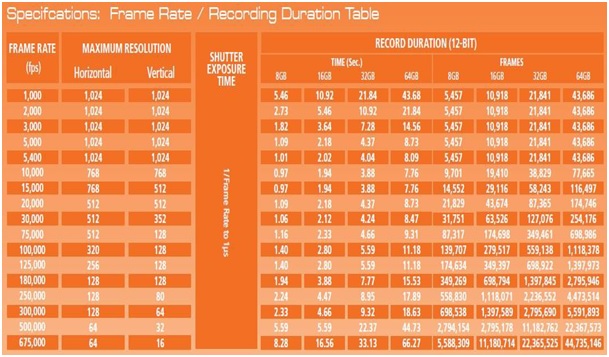

Photron FASTCAM Sa 1.1

|

Recording quality: 12-bit Frame rate (fps): Min= 1.000 fps Resolution: 1024x1024 (for 1,000 fps) |